Introduction

{getToc} $title={Table of Contents}

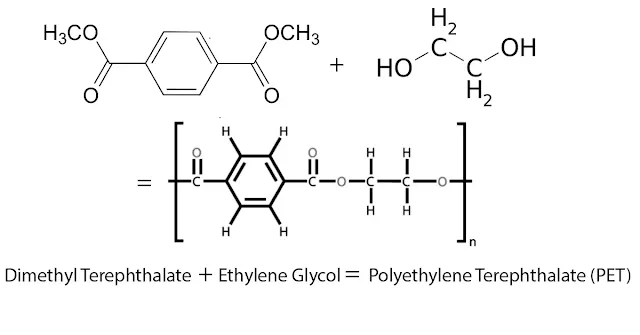

- Polyester fiber/filament is a manufactured fiber in which the fiber-forming substance is any long-chain synthetic polymer composed of at least 85% by weight of an ester of a saturated aromatic carboxylic acid.

- Polymers of monomeric units are joined by ester linkage.

- Developed by ICI (UK) Terylene in 1948, and DU Pont (USA) Dacron (1951).

- Polyesters are commonly made by the interaction of dibasic acid with dihydric alcohol.

|

| PET Production Process New |

Another Process (old)

|

| PET Production Process Old |

- Condensation reaction (280-290℃). Esterification is carried out.

- Antimony trioxide (Sb2O3) is used to start and control the reaction.

- TiO2 is added to make polyester fiber/filament dull.

- When the desired degree of polymerization is reached, the colorless polyester is extruded.

Dyeing Process

Dispersion of dispersed dye into the water

↓

Adsorption of the dye onto the fiber surface

(at HTHP method 130-140℃, at carrier method at 80℃)

↓

Diffusion of dye molecules from the surface to the interior of the fiber

Production Flow Chart

Preparation of raw materials

↓

Mixing tank

↓

Polymerization in the reactor

(Temperature 260-290℃, 3-6 hrs) (Ester interchange, polycondensation reaction)

↓

↓

Melt SPG

↓

Polyester filaments (Mono/multiplication)

↓

↓

Reeling onto a package or texturization)

Polymer Characteristics

DP = 115-140

Length = 120-150 nm

Thickness = 0.6 nm

Chemical Groups:

-CH2- = Methylene

-CO = Carboxyl

-OCO- = Ester

End Uses of Polyester

- Apparel and house furnishings

- From shirts to pants to jackets and hats

- Bedsheets

- Blanket upholstered

- Furniture

- Car tires

- Safety belts

- Coated fabrics

Characteristics of Polyester

- It is strong, very durable, quick-drying, wrinkle resistant, mildew resistant, retains its shape, and is hydrophobic in nature.

- It does not absorb water, but it can be produced in such a way that (as in polypropylene and microfibers) wicks water away from the skin.

Physical and Chemical Properties

Tags

Synthetic Fibers