Introduction

{getToc} $title={Table of Contents}

- Polyamides are polymers whose monomeric units are joined by the amide (-NH-CO-) linkage (at least 85%).

- They contain aliphatic or cyclo-aliphatic units, often known as nylons.

- Polyamides are synthesized by a condensation reaction between diamine and diacid, where the repeating units are held together by amide links.

- In 1939, the first polyamide in the USA was produced from adipic acid and hexamethylene diamine named polyamide 66.

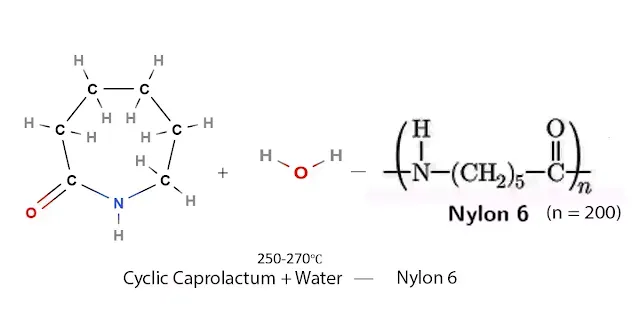

- In 1938, German caprolactam was polymerized to form polyamide 6 (Nylon 6).

Synthesis of Nylon 66

|

| Synthesis of Nylon 66 |

Synthesis of Nylon 6

|

| Synthesis of Nylon 6 |

Extrusion of Nylon

- Polyamide fibers/filaments are melt spun.

- Dry N2 is used to prevent oxidation.

- Extrusion temperature Nylon 66 (280- 290℃), Nylon 6 (250-270℃).

- Spinneret holes dia 0.1-0.4 mm.

- Extrusion velocity is normally 1000-1200 meters/min.

- After extrusion, it passes through a cooling chamber almost 5 meters long.

- The filaments are then moisturized through steam or spin finish to absorb a small amount of water (MR% 4.0-4.5).

- The filaments are drawn at a drawing ratio of 4-5 in the cold drawing method for apparel used and carpets.

- Stronger yarns are required for demanding applications drawn at a higher temperature, then texturized, and finally heat set.

- Heating-Nylon 66 (180-200℃)-Nylon 6 (160-180℃) in the presence of steam.

- Induce the annealing process.

- The estimated polymer length is 90-140 nm.

- The estimated polymer thickness is 0.3 nm.

Properties of Nylon

End Uses of Nylon

- Swimwear, skiwear, sportswear, lingerie.

- Extensively used as carpet fibers.

- Wool/Nylon (80: 20) blend.

- High-tenacity tire cord, adhere to rubber.

- Reinforced rubber in drive belts, and conveyor vehicle airbags.

Tags

Synthetic Fibers